PRODUCTION APPLICATION STUDY ON MAGNETO-HYDRO-DYNAMIC STABILITY

OF LARGE PREBAKED ANODE ALUMINUM REDUCTION CELL

Ruan Shaoyong1, Yan Feiya1, Marc Dupuis2, Valdis Bojarevics3, Zhou Jianfei1,

1CHALIECO GAMI Guiyang Guizhou China 550081

2GéniSim Inc., 3111 Alger St., Jonquière, QC, Canada, G7S 2M9

3University of Greenwich, School of Computing and Mathematics

30 Park Row, London, SE10 9LS, UK

Keywords: aluminum reduction cell; magneto-hydro-dynamic stability.

Abstract

This paper introduces the MHD stability theory of pot, and

The magneto-hydro-dynamic stability of an aluminum reduction

establishes the 3-dimensional calculation model of MHD stability

cell has an important influence on aluminum electrolysis

of pot as per actual pot dimension and busbar arrangement, as

production. The paper introduces the research theory of magneto-

well as compares the calculation against observations in one

hydro-dynamic stability of a cell and puts forward the concepts of

certain smelter operating 340kA pots in China.

“stationary state” and

“transient state” of a reduction cell. A

magneto-hydro-dynamic stability software is then used to

Magneto-hydro-dynamic stability theory

calculate two different cell conditions. The calculated results

prove to be consistent with the actual production, which confirms

Definition of pot production states

the model validity.

The large prebaked anode aluminum reduction pot can be

Introduction

mathematically represented into

2 states under production

conditions. One is called “stationary state”, namely the pot is

Aluminum reduction pot consists of carbon anode, bath melt,

under non-disturbance conditions with stable current and without

metal melt and carbon cathode. Large DC passes through the

anode change, tapping, anode effect (AE) and breaking feeding.

aluminum busbar, the anode, the bath, the metal and the cathode

Such state is a kind of ideal state, that never really occur during

etc. during aluminum reduction, which generates hundreds of

actual production, generally pots are continuously disturbed by

Gauss strong magnetic field, and the magnetic field in the pot

normal process operations. The other one is called

“transient

interacts with the current in the metal to generate the

state”, namely the pot is under disturbance conditions with current

electromagnetic force which accelerates the metal circulation in

fluctuation, anode change, tapping and breaking feeding which

the pot, with the result that on one hand it is an efficient way to

can not be prevented. In short, “stationary state” is a state without

dissolve alumina in the bath and then reduce it to aluminium, but

any temporal disturbances, and “transient state” is a state where

on the other hand causes metal pad fluctuation, so that the current

temporal disturbances are present.

efficiency (CE) is reduced and the energy consumption must be

increase in order to prevent excessive metal pad fluctuation. In

Mathematic definition of MHD stability of pot

severe cases, the metal can splashes from the pot to cause

accident[1].

For the “shallow water” approximation the horizontal dimensions

Lx and Ly are assumed to be much larger than the typical depth

The study on the conditions that generate metal pad fluctuation

H, and the interface wave typical amplitude A is assumed to be

caused by the magnetic force in the pot are called magneto-hydro-

small relative to the depth.

dynamic (MHD) stability studies in the aluminum industry. With

the development of large reduction pot, the pot capacity gradually

With the purpose to derive weakly nonlinear shallow layer

increases, so the MHD stability has become the core issue in the

approximation Boussinesq equations for the wave motion we will

large pot design, as well as the important index reflecting the

need to estimate the terms in the full three dimensional Navier-

merits of pot design. Generally the pot having good MHD

Stokes equations of motion. Nondimensional fluid flow equations:

stability is characterized by better busbar arrangement, better

continuity, horizontal momentum and vertical momentum

magnetic field distribution, low voltage fluctuation noise, and

transport, are respectively[2,3,4,5]:

better CE and power consumption index.

−1

∂

u

+δ

∂

w =0

(1)

k k

z

Therefore, MHD stability studies has practical significance,

1

analysing the various input conditions and physical parameters

∂

u

+u

∂ u δ−

w∂

u

=

t

j

k k j

z

j

that are affecting the pot stability performing mathematical

−1

−2

simulation of the metal pad fluctuation affected by the pot design

−∂

p+Re

(δ

∂

ν ∂

u +∂

ν

∂

u

)+E f

(2)

j

z e z j

k e k

j

j

and process operation. Researchers have kept exploring and

1

perfecting the calculation method of the MHD stability for years

∂

w+u∂ w

+δ−

w∂

w=

t

k

k

z

in aluminum industry, yet it seems from the published literature

−1

−1

−2

−1

that there are only few experts and scholars who can successfully

−δ

∂

p+Re

(δ

∂ν∂

w+∂ν∂

w)+E

f

−

δ

(3)

z

z e z

k e

k

z

solve the issue of MHD stability calculation.

1

When the depth averaging procedure is applied to the horizontal

momentum equations (2) we obtain:

∂u

+u

∂

u

=

t

j

k

k

j

−1

−∂

p(H

) −ε∂ ς

−

µu

+Re

∂

ν

∂

u

(4)

j

0

j

j

k e

k

0

j

1

2

2

+

Ef

−

δEH

∂

f

+O(ε

,δ

,εδ )

j

2

i

j

0z

The momentum (4) and continuity (1) equations for the two fluid

layers can be combined in a single nonlinear wave equation for

the interface ζ(x,y,t).

ρ

µρ

ε

∂

ς +

ε

∂

ς +ε ρ

∂

ς

=

tt

t

jj

H

H

1

(5)

E ∂ f

−δE

H

∂

f

j

j

2

jj

z

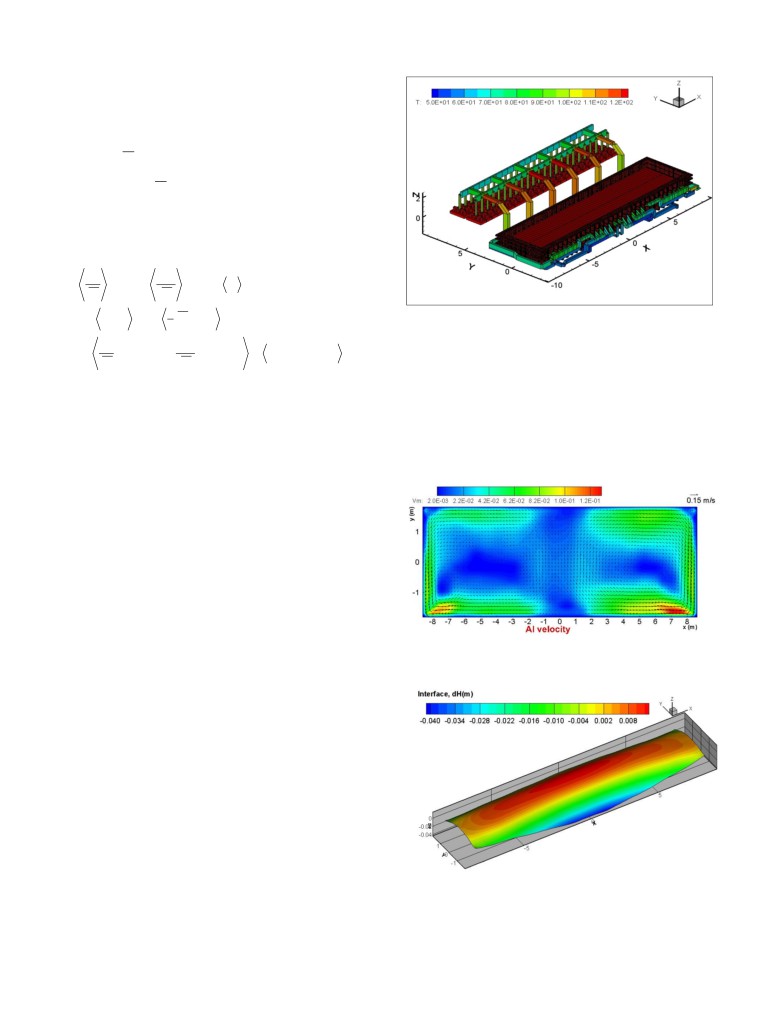

Figure 1. Model of 340 kA pot including busbar layout

ρ

µρ

−ε

∂

(ςu

)

+

∂

(ςu

)

−

ρ∂

(u

∂

u

)

tj

jo

j

jo

j

k

k

j

Initial “stationary” state

H

H

The equation (5) is used for the numerical solution of the interface

Before solving in full non-linear transient mode, it is

waves development with coupling to the horizontal circulation

advantageous to solve first the “stationary” state in order to be

obtained from the numerical solution of (4).

able to screen out quickly less promising design based on some

design criteria like the maximum vertical component of the

The equations are by definition transient but depending on the

magnetic field (Bz), maximum horizontal current component in

initial conditions and in the absence of further perturbations could

the metal pad (Jy), maximum metal pad velocity and maximum

converge to a “stationary state” where the solution is no longer

deformation of the metal surface per example.

changing when time pass. That “stationary state” solution can be

characterized with high or low

“permanent” metal pad

deformation and by high or low horizontal circulation flow.

Physical definition of pot MHD stability

It concludes that from the above-mentioned arguments the study

on the pot MHD stability should have 2 objectives: 1. quickly

study the

“stationary state” solution trying to identify

characteristics of a stable design; 2. generate a perturbation and

carry a much longer fully non-linear “transiant state” analysis to

really check if the cell design is predicted to return on its

“stationary state” after such a perturbation.

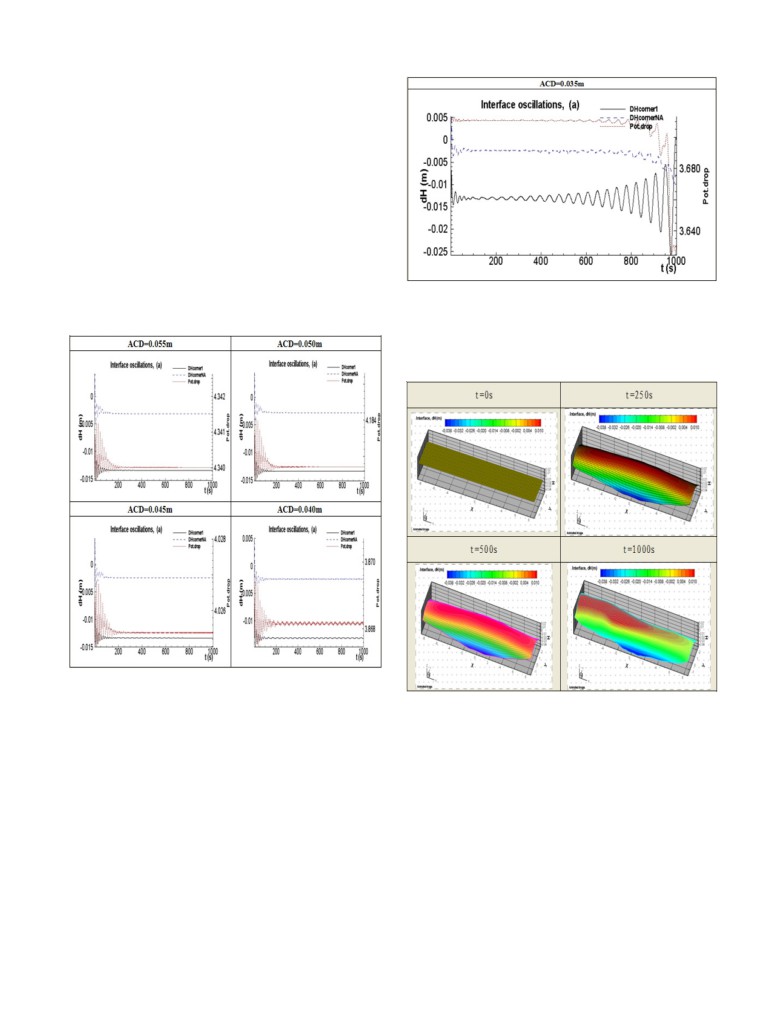

Figure 2. Initial “stationary” state metal flow under ACD

In summary, the issue of pot MHD stability can be defined as

= 0.045m

follow: disturbances happen on the pot under normal production

conditions or in some special conditions like when some anodes

are removed, the pot can then return the its original state or transit

to the new stable state after certain time. If it does, the pot is

regarded as stable under such normal production state or special

conditions, otherwise it is regarded as unstable.

Calculated results under normal conditions

Calculation model of pot and busbar layout

Using the MHD-Valdis[2] computer software, the relevant

parameters regarding pot and busbar layout are input it according

to a particular form, thus obtains a model of 340KA pot and

busbar layout in a aluminum smelter. The resulting geometry

setup of the model is shown in figure 1.

Figure 3. Initial “stationary” state metal surface under

ACD = 0.045m

2

Voltage fluctuation result chart

As we can see in figures 2 and 3, the initial “stationary” state of

the

340 kA pot looks quite acceptable with a low velocity

symmetric recirculation flow pattern (maximum of 12 cm/s) and a

symmetric and acceptable maximum surface deformation (less

than 5 cm). Unfortunately, solving only the initial “stationary”

state is not enough to know if the pot will be stable in operation,

for that the full non-linear transient solution must be solve as well.

The pot voltage fluctuation after an initial perturbation is

calculated under different anode-cathode distances

(ACD)

including 0.055m, 0.05m, 0.045m and 0.040m. The results are

presented in figure 2 for 3 variables including corner anode ACD

on the downstream duct end, corner anode ACD on the upstream

at tapping end the total pot voltage are selected. Pot voltage

fluctuation resulted from metal fluctuation is observed for that

Figure 5. Voltage fluctuation chart under ACD = 0.035m

whether it becomes stable as time goes on.

Metal surface fluctuation chart

As time goes on, under ACD 0.035m the metal surface fluctuation

chart is as follows:

Figure 4. Voltage fluctuation chart under ACD between

0.040m and 0.055m

Figure 6. Metal surface fluctuation chart under ACD

It shows that the pot can remain stable as the ACD reduces to

= 0.035m

0.040m, but if the voltage fluctuation increases, the conditions

reflected in the production are that the noise increases.

It shows clearly that the metal surface fluctuation is out of control

broadly and the metal could eventually splashed out of the pot to

In order to make distinction and comparison, the voltage

cause an accident.

fluctuation under ACD 0.035m is calculated.

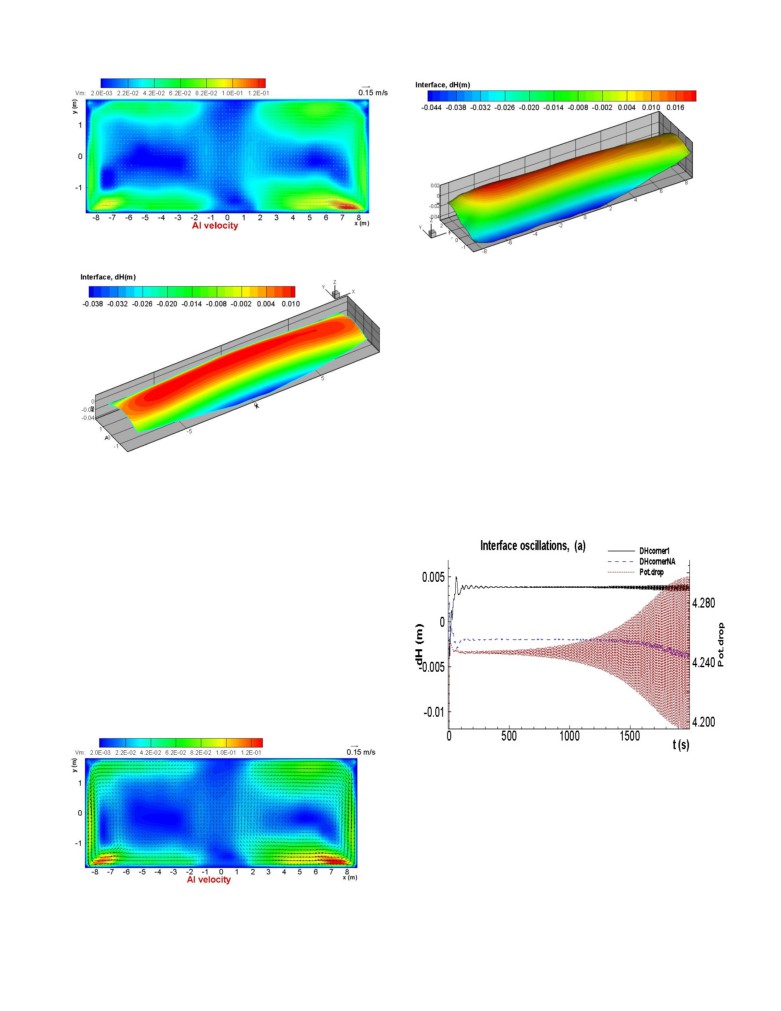

Final “stationary” state

It shows that as time goes on the metal fluctuation increases

Notice that if the pot is predicted to be stable, “transient” state

gradually under the corner anode on the downstream duct end

under ACD 0.035m, thus brings out the much voltage fluctuation

triggered by the perturbation will

“converged” back into a

of the total pot, which may generate short-circuit risk. Therefore

“stationary” state that will by definition no longer evolves as time

this illustrates the pot is impossible to remain stable under ACD

pass.

0.035m.

3

Figure 7. Final “stationary” state metal flow under ACD

= 0.045m

Figure 10. Initial “stationary” state metal surface under

ACD = 0.045m

As we can see comparing figures 2 and 3 with figures 9 and 10,

the initial “stationary” state metal flow is not much affected by the

“permanent” removal of the 2 anodes but the initial “stationary”

state metal surface is quite affected as the metal surface

deformation is no longer symmetric and the maximum

deformation has increased to 6 cm.

Voltage fluctuation result chart

So clearly removing anodes is not good for the pot MHD stability

but again only by running the full non-linear transient analysis

will we know if the pot will remain stable under those special

Figure 8. Final “stationary” state metal surface under

conditions. Under ACD 0.045 m, with 2 corner anodes removal

ACD = 0.045m

on downstream duct end, the pot voltage fluctuation chart is as

follows:

As we can see comparing figures 2 and 3 with figures 7 and 8,

after being affected by the perturbation, the pot is predicted to

settle back into the initial “stationary” state which may not be

systematically the case.

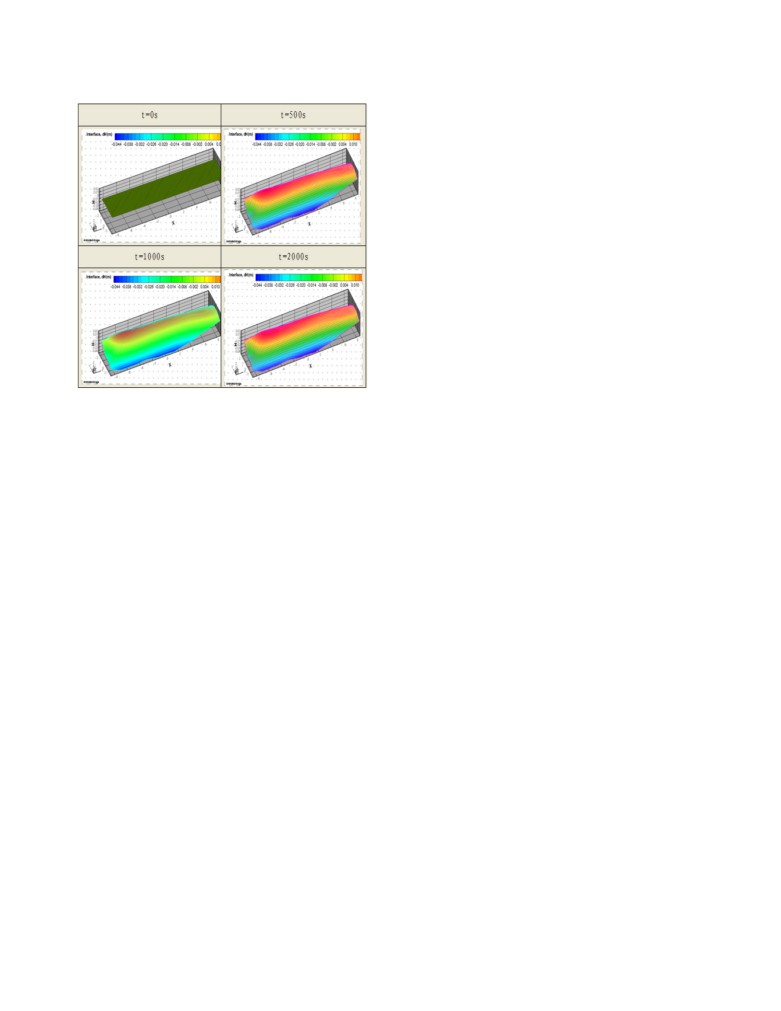

Calculated results with some anodes removed

The premise of calculation of MHD under special conditions is

that the 2 corner anodes on downstream duct end are removed, in

this case obverses whether the voltage fluctuation and metal

surface fluctuation is in control as time goes on.

Initial “stationary” state

The “stationary” state in the context of this special anode removed

conditions assumes that those anodes have been permanently

removed.

Figure 11. Voltage fluctuation chart with anode removal

of ACD=0.045m

With anode removal, as time goes on the pot voltage fluctuation

increases gradually, it shows that the pot design is not very robust,

and the MHD stability in anode change conditions is worse than

in normal conditions.

Figure 9. Initial “stationary” state metal flow under ACD

= 0.045m

4

Metal surface fluctuation chart

1) Under normal conditions, the calculated pot voltage can be

minimized to 3.87 V while the noise is high.

2) Under normal conditions, if ACD is 0.040 m or more, the pot

can remain stable.

3) The pot is sensitive to the anode change under ACD 0.045 m,

so the pot can have instability period after anode change

unless the ACD is more than 0.045 m, and hence the power

consumption need to be increased.

4) As per statistics, generally the full current passes through

new anodes 8 hours after they are put in the pot, so the pot is

in special anode change conditions within one-third of the

time of all day. Due to cyclic occurrence of anode change

every day, the pot suffers an impact within 8 hours every

day, which will certainly cause the successive unbalanced

energy.

Conclusions

From the above-mentioned calculation and analysis, it can be

conclude as follows:

Figure 12. Metal surface fluctuation chart with anode

1)

As the pot capacity increases, it will become more and more

removal of ACD= 0.045m

important to study the MHD stability which has the value of

directing design and operating conditions.

It shows that: under ACD 0.045m, with 2 corner anode removed,

the pot is predicted experience significant metal pad fluctuation,

2)

For the design of MHD stability, the normal conditions and

in this case the conditions reflected on the control system of

the special anode change conditions of pot must be

master computer is that the pot voltage noise has increases

calculated fully.

significantly.

3)

The calculation model of MHD stability in this paper is

Conditions observed in production

reasonable, calculated results and conditions observed in

production match pretty closely, thus confirming the value

This kind of pot has been in production for years, and it

of the MHD-Valdis software for the purpose of production

conditions observed in production are summarized as follows:

applications.

1) The pot voltage was minimized to about 4.0 V.

References

2) Under the conditions without anode change, metal tapping

and AE, the pot is in good condition all the day without

[1]

Liu Jie, Li Jie. “Study on magnetic field distribution of 350

voltage fluctuation.

kA prebaked anode pot” Mining and Metallurgical

Engineering: 2008, third phase in 28th volume, 71-75.

3) Once the pot has anode changed, generally within 8 hours it

has bad stability, high noise and heavy voltage fluctuation, in

[2]

V. Bojarevics and M. V. Romerio. “Long waves instability

this case even through the voltage is increased appropriately,

of liquid metal-electrolyte interface in aluminium

it is hard to control the conditions.

electrolysis cells: a generalization of Sele’s criterion”. Eur.

J. Mech., B/Fluids, 13 (1994), no 1, 33-56.

4) Since the pot has anode change every day, the pot voltage

fluctuation is a cyclic occurrence in sync with the cyclic of

[3]

V. Bojarevics and K. Pericleous, “Shallow Water Model for

anode change time, thus brings out that the process technical

Aluminium Electrolysis Cells with Variable Top and

conditions are hard to be stabilized quite often.

Bottom”. In Proc. TMS Light Metals (2008), 403-408.

[4]

V. Bojarevics and K. Pericleous, “Solution for the metal-

Comparison of calculated results

bath interface in aluminium electrolysis cells”. In Proc.

vs conditions observed in production

TMS Light Metals (2009), 569-574.

The conditions observed in production are compared with the

[5]

V. Bojarevics,

“MHD-Valdis Reference Manual”.

calculated results of pot MHD stability, and the analysis is as

University of Greenwich (2006).

follows item by item:

5